Ribon was re-elected as the Chairman Unit of the 7th Mechanical Equipment Branch of the CMA

The 6th Council of the China Meat Association, with the support of governments at all levels and the joint efforts of me...

READ MORE

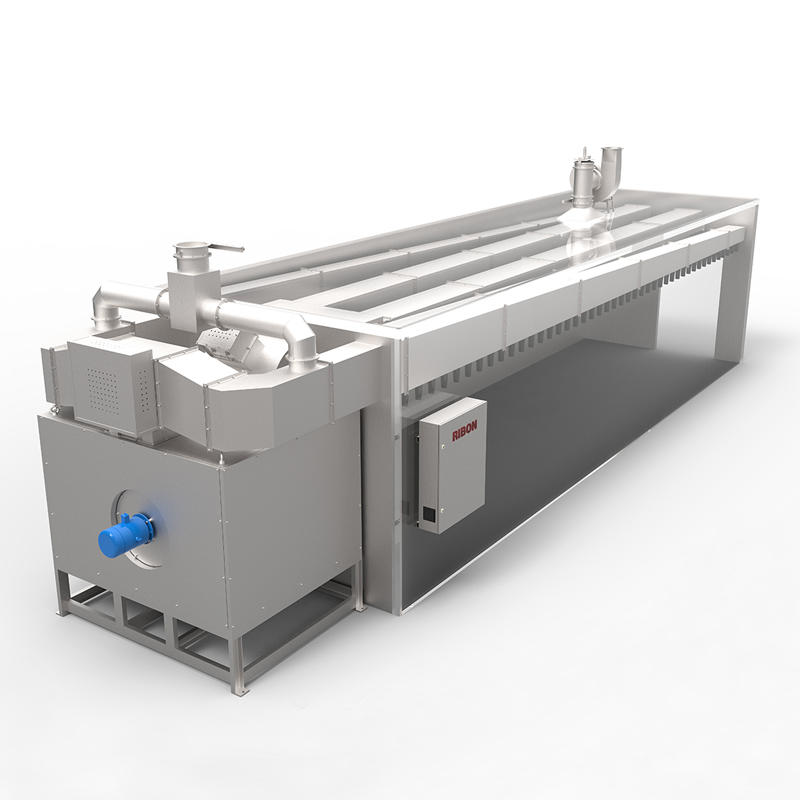

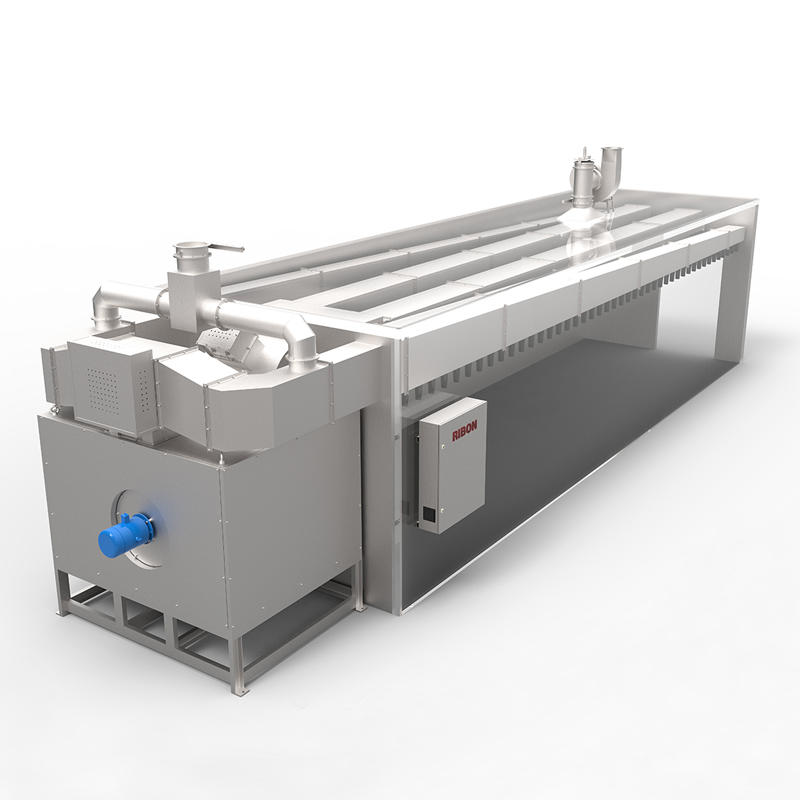

Air conditioning solutions are different from traditional dryer. It includes driving system, heating system, air circulation system, air amount dynamic control system, adjustable air return system and exhaust system.

●Characteristics:

◇Controllable temperature according humidity.

◇Less drying time with better consistency.

◇Directly use room as dryer chamber to save the purchase cost.

◇Adopt central heat exchanger with large exchanging area.

◇Adopt single central circulation fan to offer big air flow and stable air pressure.

◇Adopt special air duct in both sides to ensure the air consistency.

◇Adopt special air damper system to make the air move periodically

◇Adopt special controllable air return system to keep the air consistency.

◇Adopt PLC and Touch screen control system.

Zhejiang Ribon Intelligent Equipment Co., Ltd. was founded in 2003 by Mr. Shi Ming and we specialize in the R&D and manufacturing of meat processing machinery. Meat Processing Smokehouse Air Conditioning Suppliers and Company in China.

As a professional enterprise of meat processing smokehouse, vacuum tumblers and cutting and deboning lines in China, we also exported these solutions to the world since the year of 2003.

The technology and solutions have always been optimized and now Ribon's solutions are widely in use across the whole world. And we will constantly develop our systems further, to bring you better technologies and service.

The 6th Council of the China Meat Association, with the support of governments at all levels and the joint efforts of me...

READ MORE

Meat processing smokehouses are an integral part of the culinary world, bridging tradition with modern technology to cre...

READ MORE

A well-designed and properly maintained smoke chamber is essential for the safe and efficient operation of a fireplace. ...

READ MORE

When it comes to fire safety and efficient operation, the smoke chamber in a fireplace plays a crucial role. Often overl...

READ MOREProduct Knowledge