Understanding the Importance of Smoke Chambers in Fireplaces

When it comes to fire safety and efficient operation, the smoke chamber in a fireplace plays a crucial role. Often overl...

READ MORE

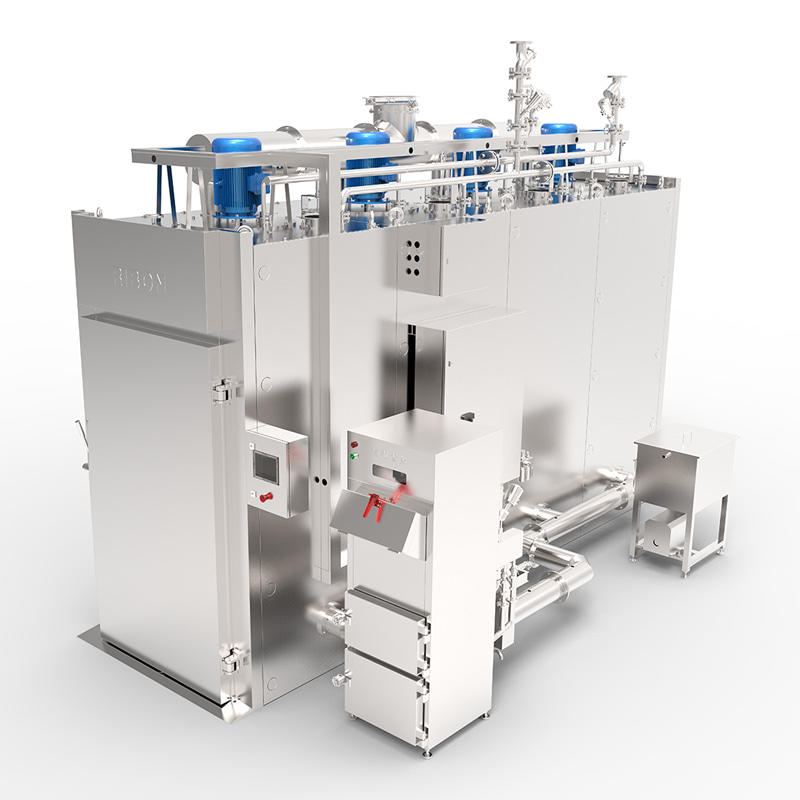

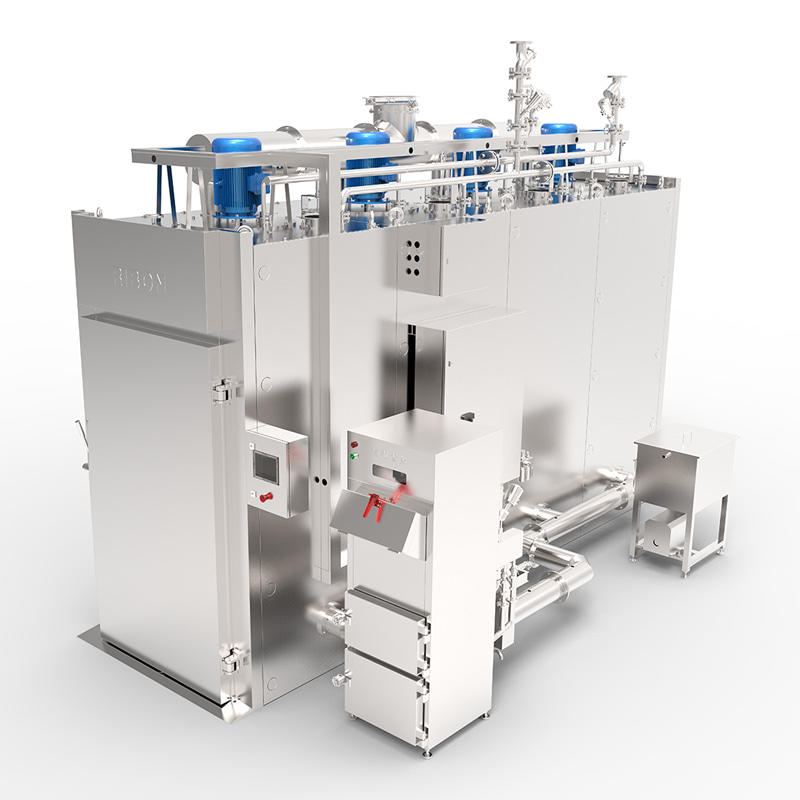

●Function:

Drying, Cooking, Smoking, Reddening, Showering

Optional Cold smoking and baking

| ●Heating Resources: Steam, Electric, NG, LPG |

●Smoking Options Woodchip smoking or liquid smoking |

●Capacity: 1- 8 trolleys flexible design |

●Characteristics:

◇PLC+ Touch screen controlling system

◇The fault diagnosis function of the system

◇The running status of the machine can be recorded and reset

◇The machine can restart with all the original working data

◇Specially designed air circulation system

◇PID temperature control mode

◇Optimal CIP cleaning system.

◇Modular construction of the chambers

◇Isolation material is Polyurethane foam or rock wool inside the chamber wall

◇Adopt a special fan with low airspeed and high air pressure

◇Woodchip smoke generator or liquid smoke atomizer

◇The humidity-controlling valve is equipped

◇Adopting the Lind Weit draining valve

◇World-famous electrical and pneumatic components

RYX Series

|

Trolley |

Capacity(kg) |

Power(kW) |

Electric heating Power(kW) |

Steam consumption(kg/h) |

|

1 |

250 |

6.1 |

30 |

40 |

|

2 |

500 |

10.1 |

60 |

80 |

|

3 |

750 |

14.1 |

90 |

120 |

|

4 |

1000 |

18.1 |

120 |

160 |

RYXN Series

|

Trolley |

Capacity(kg) |

Power(kW) |

Steam consumption(kg/h) |

|

2 |

500 |

9 |

80 |

|

4 |

1000 |

17 |

160 |

*The above technical data is for reference only, it may change according to different configurations.

Zhejiang Ribon Intelligent Equipment Co., Ltd. was founded in 2003 by Mr. Shi Ming and we specialize in the R&D and manufacturing of meat processing machinery. Vertical Airflow Smokehouse Suppliers and Company in China.

As a professional enterprise of meat processing smokehouse, vacuum tumblers and cutting and deboning lines in China, we also exported these solutions to the world since the year of 2003.

The technology and solutions have always been optimized and now Ribon's solutions are widely in use across the whole world. And we will constantly develop our systems further, to bring you better technologies and service.

When it comes to fire safety and efficient operation, the smoke chamber in a fireplace plays a crucial role. Often overl...

READ MORE

In order to better improve the after-sales service, our company organized the 22nd technical training seminar in the com...

READ MORE

Versatility: One of the primary advantages of commercial smokehouses capable of both hot and cold smoking is their versa...

READ MORE

Hot Smoking: Hot smoking involves cooking and smoking the food simultaneously at temperatures typically ranging from 165...

READ MOREProduct Knowledge